Mark was rearranging his ute when he came to pick up the boys one afternoon, he threw a plastic down pipe of cut on the ground which was destined for the bin. I snapped that up as it was just the right size it just needed a little alteration, a snip here a snip there and less mess.

With two wood lathes a Jet Mini VS which has 1"x10tpi on the spindle and my Nova 3000 which has 30mm x 3.5 my seven chucks I have a number of adaptors which fit the chucks to fit each lathe each chuck has different jaws fitted. These adaptors have to be changed if I wish to use the particular set of jaws on a job on the other lathe.

As I had altered the Independent four jaw chuck to 1"x10tpi I also want it to fit the Nova 300 so set about making a 30mm x 3,5 to 1" x 10tpi adaptor. This also allows me to use those chucks set up for use on the jet mini on the Nova without much hassle.

I am only a novice in machining and over the years have followed many a forum and youtube on machining to all those who gave clear and concise instructions many thanks. I have learnt much in doing this project.

I had paid a visit to Edcon where I had explained what I wished to make and left it to them to help me choose the required material/s, I bought other stock round bar also.

For this particular job it was suggested I try/use 4140 and I chose a nice 60mm round off cut twice the length required (you never know).

Once again as this wasn't done overnight in a day or even a week as explained in previous posts.

Once again as this wasn't done overnight in a day or even a week as explained in previous posts.With my little $5 camera well out of action by now and use of new phone when I thought about it the WiP shots were few and far between.

Well I meant to write 4140 on the bar end not 1041.

Machining down to required 1" dia for the external thread. Centre bored out to 15mm.

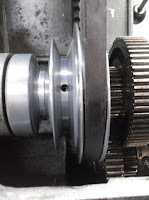

The 1st gear change from what had been set prior purchasing the lathe to the required set up for cutting the internal 30mm x 3.5 thread.

The last time I had ever done this was in year 4 now year 10 in metal work at high school.

Changing the gears using the Myford chart ad double checking a few other charts showed I required.

This gear change didn't happen easy as they had not been removed in many years, gum had formed along splines, I had to tap the lead screw gear off very carefully. I then spent half a day cleaning all the gears and splines of sticky residue.

Ken came over and helped set up both lots of gear changes although I had fitted the gears required for the metric gear cutting I felt I needed someone more experienced to check on what I had done. The second change ken also came and ran through what to do again.

The above photos are prior camera death and show the new set up.

The test cut on external using the 30mm x 3.5 set up to check. I just use a large format Felt Tip pen to blue it. I was spot on.

All set up to cut internal thread. I was using my new boring bar set from Hare & Forbes, I had to re-grind the relief angle of the underside as the 2nd cut had it also cutting a 2nd thread.

Thetopslide was set to 30 deg's, slow rpm, and .010 then .005 cuts with final cuts as small as .001 and spring cuts. Testing the fit of the adaptor, I had to leave the Myford chuck attached to the work piece as the whole set up for thread cutting would not be easy to go back to if I had removed the adaptor from the Myford chuck.

Testing the fit of the adaptor, I had to leave the Myford chuck attached to the work piece as the whole set up for thread cutting would not be easy to go back to if I had removed the adaptor from the Myford chuck.The photo to the left is prior machining the collar in the adaptor.

Below the internal 30mm x 3.5 thread and shoulder cut.

The snug fit test of the 30mm x 3.5 internal thread onto the Nova 3000

Below test cut of the 1" x 10tpi thread.

Below left 1st Test fit of the Nova chuck with the 1" x 10tpi thread cut

The adaptor all done except the holes drilled for the Tommy bar for ease of removal off the shaft.

During he machining of the project I found one of the pulley grub screws on the Myford had come loose. This came to light when the motor was spinning but the chuck was not.

One of the things required to do when using the back gears of the Myford ML7 is the adjustment of the grub screw it requires to be moved/slid to the edge of the gear bringing the back gears into play. An Alan Key with the short length ground fits best. It also must be replaced and locked when finished.

Excuse the gloves I am trying to avoid my Sirius from flaring up as much.

I ran the adaptor and Nova chuck on the Nova lathe at 850rpm and visually there is not or minimal run out.

No comments:

Post a Comment

Your comments are welcome please forgive us if not replied to immediately.